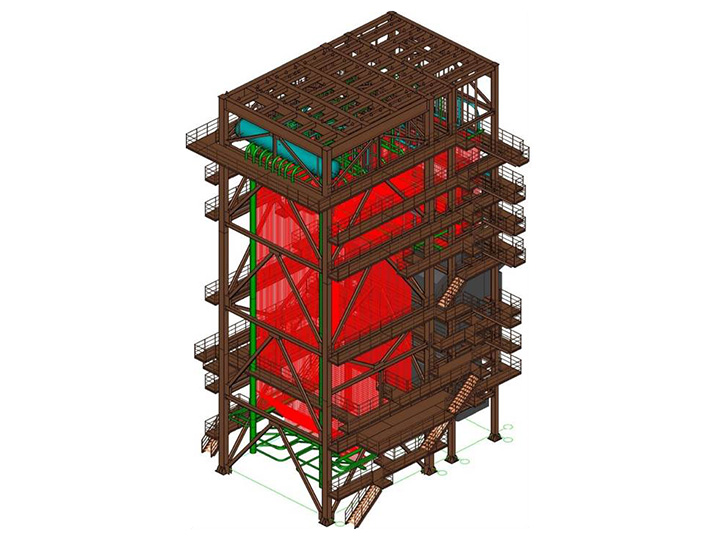

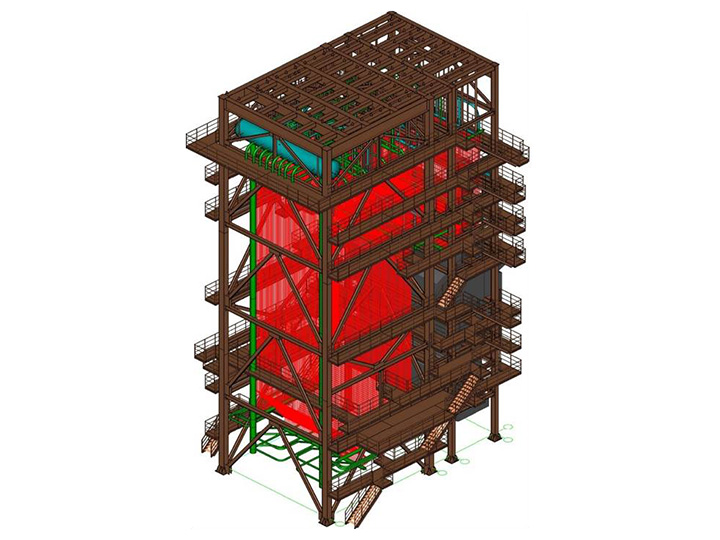

Efficient clean combustion industrial pulverized coal furnace

Boiler capacity:

Steam oven: 10-65t/h

Water heater: 7-46MW

Boiler parameters:

Pressure: 1.0-3.82MPa

Temperature: 184-450 ° C

Pressure: 1.0-1.6MPa

Temperature: 95-150 ° C

Boiler fuel: AII, AIII bituminous coal

New energy-saving and environment-friendly pulverized coal angle tube:

The new energy-saving and environment-friendly pulverized coal angle tube boiler is the third generation of new energy-saving and environment-friendly industrial pulverized coal furnace jointly developed by Shanghai Industrial Boiler Co., Ltd., Shanghai Jiaotong University and Shanghai University of Technology. It has high efficiency, environmental protection, energy saving and coal type. Advantages such as strong applicability.

The company's main products:

Boiler capacity:

Steam oven: 10-65t/h

Water heater: 7-46MW

Boiler parameters:

Pressure: 1.0-3.82MPa

Temperature: 184-450 ° C

Pressure: 1.0-1.6MPa

Temperature: 95-150 ° C

Boiler fuel: AII, AIII bituminous coal

Boiler features:

a. The boiler has a small footprint, light overall weight and low capital investment;

b, high thermal efficiency and low operating cost;

c. Adopting a new high-efficiency low NOx burner (with patent for swirling pulverized coal burner) and a high temperature combined vortex burnout device;

d, the installation workload is small, the installation period is short;

e, wide range of load regulation and rapid response;

f. The boiler has a beautiful appearance and a good operating environment.

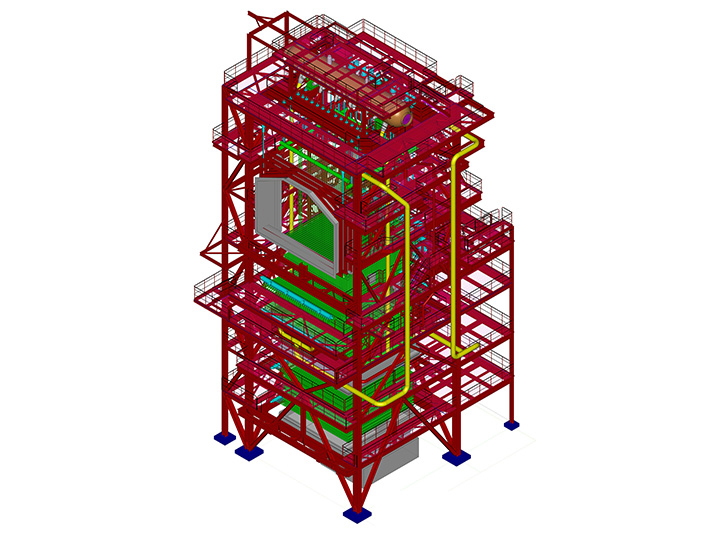

High efficiency pulverized coal furnace:

Boiler capacity:

Steam oven: 75-240t/h

Water heater: 46-116MW

Boiler parameters:

Pressure: 3.82-9.8MPa

Temperature: 450-540 ° C

Pressure: 1.25-1.6MPa

Temperature: 115-150 ° C

Boiler fuel: AII, AIII bituminous coal, lean coal, etc.

Boiler features:

a. Centralized supply of pulverized coal: The pulverized coal is concentrated and uniformly supplied by the milling factory, and the quality of pulverized coal is stable.

b. Friendly working environment: The whole system is closed and operated, automatically coal, concentrated ash, and no dust.

c. The boiler starts and stops simply: the boiler system can be opened and stopped immediately, and the ignition source is cut off for 30 seconds to enter normal operation; the coal powder supply can be shut off to realize the shutdown.

d. high efficiency and energy saving: pulverized coal combustion is sufficient, boiler heat transfer effect is good, air excess coefficient is small, and system thermal efficiency is high.

e. Clean emission: pulverized coal boiler can be desulfurized in the furnace. The burner adopts low-temperature air grading design, the combustion temperature field is uniform, avoiding local high temperature, and the SO2 and NOX content generated by the combustion process is low; the flue gas is dedusted by bag, and the dust emission concentration is Low; the fly ash collected by the bag filter is discharged through the closed system for centralized treatment and utilization without secondary pollution.

f. Arrange the burners reasonably to make the fuel ignite quickly: there is a good aerodynamic field in the furnace to make the heat load of each wall uniform; it is necessary to make the flame full in the furnace and reduce the dead zone of the airflow. Also avoid the flame from rushing through the wall and avoiding slagging.

g. The furnace should have sufficient volume and height to ensure the residence time of the fuel in the furnace and complete combustion.

h. It is possible to arrange the appropriate evaporation heating surface to meet the boiler capacity requirements: the furnace outlet flue gas temperature is appropriate to ensure that the heat-receiving surface does not slag and safely work on the day after the sling.

i. The furnace structure is compact, and the amount of metal and other materials is small; it is easy to manufacture, install, operate and maintain.

j. The boiler layout is reasonable, and the overall layout of the boiler is neat and compact. The arrangement of the heating surfaces of the furnace and the tail is coordinated and unified, and the appearance of the boiler is beautiful and generous. It ensures the continuous, reliable and safe operation of the products supplied.

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

WNS automatic fuel gas boilerSZS automatic fuel gas boilerLarge gas boiler

Biomass boiler

Biomass boiler  Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler

Low temperature waste heat boilerSteel coking waste heat boilerNon-ferrous metallurgical waste heat boilerPetrochemical waste heat boilerCDQ waste heat boiler  Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler

Efficient clean combustion industrial pulverized coal furnaceLarge power station pulverized coal boiler  Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler

Waste boilerAngle tube boilerFuel gas organic heat carrier boilerGrate type organic heat carrier boilerEfficient clean combustion coal powder organic heat carrier boiler